| BS6724 Cables | |||

| BS 6724 Armoured Power Cables, 600/1000V |

BS 6724 Cables

BS 6724 Armoured Power Cables, 600/1000V

Multi-core 600/1000 V cables with stranded copper conductors

Application

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside

buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes

create a potential threat to life and equipment.

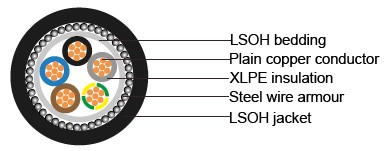

Construction

Conductor |

Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, |

|

IEC 60228. |

Insulation |

XLPE (Cross-Linked Polyethylene) Type GP 8 or ethylene propylene rubber (GP 6) |

Colour Code |

1 Core : Brown |

|

2 Cores: Brown or Blue |

|

3 Cores: Brown, Black, Grey |

|

4 Cores: Blue, Brown, Black, Grey |

|

5 Cores: Green/Yellow, Blue, Brown, Black, Grey |

|

Above 5 Cores: White Cores with black numbers |

Bedding |

LSOH (Low Smoke Zero Halogen) |

Armour |

Single Core: AWA (Aluminum Wire Armour) |

|

Multi Core: SWA (Steel Wire Armour) |

Outer Sheath |

LSOH (Low Smoke Zero Halogen) |

Technical Information

Voltage rating 600/1000V

Temperature rating 0°C to +90°C

Bending radius 1.5mm² to 16mm²: 6 x overall diameter

25mm² and above: 8 x overall diameter

Flame retardant IEC60332 part 1, BS4066 part 1

Halogen free IEC 60754, EN 50267

Smoke density IEC 61034, EN50268

Multi-core 600/1000 V cables with stranded copper conductors

Nominal Cross-sectional Area |

Strand Type |

Nominal Insulation Thickness |

Nominal Bedding |

Nominal Steel Wire Armor dia. |

Nominal Sheath Thickness |

Approx.Overall Diameter |

AprroxWeight |

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

7x1.5 |

7/0.53 |

0.6 |

0.8 |

0.9 |

1.4 |

15.2 |

500 |

12x1.5 |

7/0.53 |

0.6 |

0.8 |

1.25 |

1.5 |

19.4 |

820 |

19x1.5 |

7/0.53 |

0.6 |

0.8 |

1.25 |

1.6 |

22.2 |

1080 |

27x1.5 |

7/0.53 |

0.6 |

1 |

1.6 |

1.7 |

26.7 |

1550 |

37x1.5 |

7/0.53 |

0.6 |

1 |

1.6 |

1.7 |

29 |

1850 |

48x1.5 |

7/0.53 |

0.6 |

1 |

1.6 |

1.8 |

32.7 |

2250 |

7x2.5 |

7/0.67 |

0.7 |

0.8 |

0.9 |

1.4 |

17.1 |

730 |

12x2.5 |

7/0.67 |

0.7 |

0.8 |

1.25 |

1.6 |

22.4 |

1020 |

19x2.5 |

7/0.67 |

0.7 |

1 |

1.6 |

1.7 |

26.6 |

1530 |

27x2.5 |

7/0.67 |

0.7 |

1 |

1.6 |

1.8 |

30.7 |

1960 |

37x2.5 |

7/0.67 |

0.7 |

1 |

1.6 |

1.8 |

33.8 |

2450 |

48x2.5 |

7/0.67 |

0.7 |

1.2 |

2 |

2 |

39.3 |

3260 |

7x4 |

7/0.85 |

0.7 |

0.8 |

1.25 |

1.5 |

19.7 |

840 |

12x4 |

7/0.85 |

0.7 |

1 |

1.6 |

1.6 |

25.7 |

1390 |

19x4 |

7/0.85 |

0.7 |

1 |

1.6 |

1.7 |

29.3 |

1850 |

27x4 |

7/0.85 |

0.7 |

1 |

1.6 |

1.9 |

34.4 |

2350 |

37x4 |

7/0.85 |

0.7 |

1.2 |

2 |

2 |

39.2 |

2800 |

48x4 |

7/0.85 |

0.7 |

1.2 |

2 |

2.1 |

44.1 |

3250 |