Composite Cables |

|||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Conductor | 7/0.67mm Stranded bare copper wire |

| Insulation | XLPE. Thickness is 0.7mm. Outer diameter 3.41mm |

12C Fiber Cable

| No of fibers in loose tube | 12 fibers |

| Loose tube | outer diameter: 2.2+/-0.2mm (Aramid yarn &PE Sheath would be used over the loose tube) |

Element Assembly

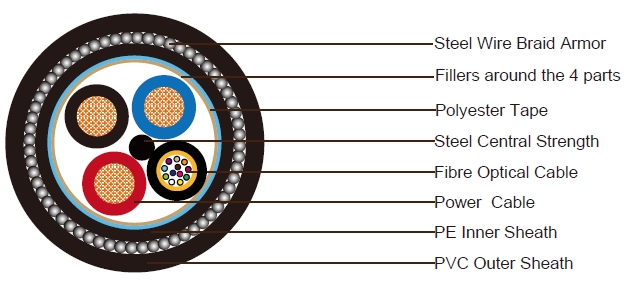

| Central Strength Member | Steel central strength member with PE/PVC coating if necessary |

| Fillers | PP fillers will be added around the 4 cable cores. |

| Wrapping Tape | Polyester tape is applied over cable core if necessary |

| Inner Jacket | PE, LSOH is optional, thickness is 1.0mm |

| Armor | Steel wire armour |

| Sheath | PE, LSOH is optional, thickness is 1.8mm, nominal outer diameter 16.2±2.0mm |

| Sheath Color | Black |

Optical Characteristics

| Property Attenuation @ 850 nm (dB/km) | 50/125 fibers ≤ 3.0 | 62.5/125 fibers ≤ 3.2 |

| Attenuation @ 1300 nm (dB/km) | ≤ 1.0 | ≤ 1.2 |

| Added Attenuation with Bending | ≤ 0.5 dB (850 and 1300 nm) for 100 turns around a 75 mm mandrel | |

| Numerical Aperture | 0.20 ± 0.02 | 0.275 ± 0.015 |

| Bandwidth @ 850 nm | 400 MHz*km | 160 MHz*km |

| Bandwidth @ 1300 nm | 800 MHz*km | 500 MHz*km |

| Core diameter | 50 ± 3 µm | 62.5 ± 3 µm |

| Cladding diameter | 125 ± 2 µm | |

| Core-Claddingoffset | ≤ 6% | |

| Cladding non-circularity | ≤ 2% | |

| Core non-circularity | ≤ 6% | |

| Coating diameter | 245 ± 10 µm | |

| Coating / Cladding offset | 12 µm | |

| Proof Test | ≥ 0.69 GN/m2 (100 kpsi) | |

The fibers contain no splices.

Mechanical Properties:

Tensile load:

Operating: 3000N

Installation: 5000N

Bending radius:

Operating: 15×OD

Installation: 28×OD

Compressive load:

Short term: 5500N

Long term: 3500N