| Fire Resistant Cable | |||

![]() Fire Resistant Cable

Fire Resistant Cable

300/500V Mica+XLPE/SR Insulated & Overall Screened Multipair Instrumentation CablesRE-2X(St)H...CI. FE 180 PH30 ( CU/MGT+XLPE/OSCR/LSZH 300/500V Class 2 )

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Circuit Integrity |

IEC 60331-21; BS 6387 CWZ; DIN VDE 0472-814(FE180); |

Circuit Integrity with mechanical shock |

EN 50200(PH30); CEI 20-36/4-0 |

Circuit Integrity with mechanical shock & water spray |

EN 50200 annex E |

System circuit integrity |

DIN 4102-12, E30 depending on lay system |

Flame Retardance (Single Vertical |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; |

Reduced Fire Propagation |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Halogen Free |

IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

Minimum Smoke Emission |

IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

No Toxic gases |

NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

300/500 V

CABLE CONSTRUCTION

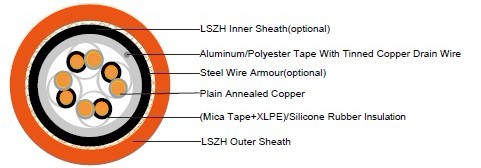

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Mica glass tape covered by extruded cross-linked XLPE compound or fire resistant

silicone rubber compound type EI2 as per BS 7655-1.1.

Cabling Elements: Insulated cores are twisted to form pairs with varying lay length to minimize

crosstalk. Two-pair cable had four cores laid in quad formation.

Cabling: Pairs are cabled together.In cables with 8 pairs or more, 4 pairs are assembled to form a

bunch, the bunches are then cabled together.

Overall Screen: Aluminum/polyester tape with 0.5mm2 screen (7/0.3mm) tinned copper drain wire.

Inner Sheath(optional):Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1

Armouring(optional): Galvanized steel wire armour

Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1(Thermosetting LSZH

compound type SW2-SW4 as per BS 7655-2.6 can be offered.)

COLOUR CODE

Insulation Colour: White with black numberings.

Sheath Colour: Orange (other colours on request).

TYPE CODE

RE- Instrumentation cable H Halogen free & zero halogen

2X XLPE 2G Silicon Rubber

(St) Static shield of aluminium tape SWA Steel Wire Armoured

FE180 Insulation integrity (950°C 180 minutes) CI Circuit integrity

PH 90 Fire Test for 90 mins at 830°C

Physical AND THERMAL PROPERTIES

Temperature range during operation (fixed state): -30°C – +70°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 6 x Overall Diameter (unarmoured cables with silicone rubber insulation)

8 x Overall Diameter (unarmoured cables with XLPE insulation)

10 x Overall Diameter (armoured cables)

Electrical PROPERTIES

Dielectric test: |

2000 V r.m.s. x 5' (core/core) |

Insulation resistance |

XLPE: ≥1000 MΩ x km (at 20°C) |

Short circuit temperature |

XLPE: 250°C |

CONSTRUCTION PARAMETERS

Conductor

|

RE-2X(St)H.CI. FE

180 PH30 RE-2G(St)H.CI. FE 180 PH30 |

RE-2X(St)HSWAH...CI. FE 180 PH30 |

||||||

| No. of Core X Cross Section | No./ Nominal Diameter of Strands | Nominal Insulation Thickness | Unarmoured | Armoured | ||||

| Nominal Overall Diameter | Approx. Weight | Diameter Under Armour | Armour Wire Diameter | Nominal Overall Diameter | Approx. Weight | |||

mm2 |

no./mm |

mm |

mm |

kg/km |

mm | mm | mm | kg/km |

1 Pairs |

||||||||

1X2x1.0 |

7/0.43 |

0.6 |

8.0 |

76 |

8.0 |

0.90 |

12.4 |

281 |

1X2x1.5 |

7/0.53 |

0.7 |

8.5 |

94 |

8.5 |

0.90 |

13.1 |

332 |

1X2x2.5 |

7/0.67 |

0.8 |

10.5 |

130 |

10.5 |

0.90 |

15.1 |

401 |

2 Pairs |

||||||||

2X2x1.0 |

7/0.43 |

0.6 |

12.4 |

120 |

12.4 |

0.90 |

17.4 |

370 |

2X2x1.5 |

7/0.53 |

0.7 |

14.0 |

160 |

14.0 |

0.90 |

18.4 |

450 |

2X2x2.5 |

7/0.67 |

0.8 |

16.0 |

230 |

16.0 |

0.90 |

20.5 |

550 |

5 Pairs |

||||||||

5X2x1.0 |

7/0.43 |

0.6 |

16.5 |

276 |

16.5 |

1.25 |

22 |

854 |

5X2x1.5 |

7/0.53 |

0.7 |

20.5 |

368 |

20.5 |

1.25 |

26.2 |

1023 |

5X2x2.5 |

7/0.67 |

0.8 |

23.0 |

518 |

23.0 |

1.25 |

28.9 |

1276 |

10 Pairs |

||||||||

10X2x1.0 |

7/0.43 |

0.6 |

20.5 |

501 |

20.5 |

1.25 |

26.4 |

1271 |

10X2x1.5 |

7/0.53 |

0.7 |

26.0 |

673 |

26.0 |

1.60 |

32.8 |

1742 |

10X2x2.5 |

7/0.67 |

0.8 |

29.5 |

971 |

29.5 |

1.60 |

36.5 |

2205 |

| 20 Pairs | ||||||||

20X2x1.0 |

7/0.43 |

0.6 |

26.5 |

917 |

26.5 |

1.60 |

33.3 |

2197 |

20X2x1.5 |

7/0.53 |

0.7 |

34.0 |

1258 |

34.0 |

1.60 |

41.2 |

2705 |

20X2x2.5 |

7/0.67 |

0.8 |

38.5 |

1830 |

38.5 |

2.00 |

46.7 |

3836 |

Note : Other conductor sizes & core configurations are available upon request.