| FIREGUARD Flame Retardant Cables | |||

![]() Flame Retardant Optic Fiber Cables

Flame Retardant Optic Fiber Cables

Flame Retardant Tight Buffered Distribution Fiber Optic cablesMTA-B-C-D-Y |

Flame Retardance (Single Vertical |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE |

Reduced Fire Propagation |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Note: Asterisk ** denotes that the standard compliance is optional, depending on the oxygen index of the PVC compound and the cable design.

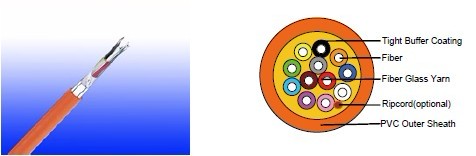

CABLE CONSTRUCTION

Optical fibers: Singlemode and multimode tight fibers, with tight buffer coating.

Reinforcement: Either aramid yarn or fiber glass is wound around the tube to provide physical

protection and tensile strength, with added fire protection.

Inner Sheath(optional): Thermoplastic PVC compound type LTS3 as per BS 7655-6.1

Ripcord(optional): An optional ripcord can be located under the outer sheath to facilitate jacket

removal.

Armouring(optional):

STA: Corrugated steel tape armour

SWB: Steel wire braid

Outer Sheath: Thermoplastic PVC compound. UV resistance, hydrocarbon resistance, oil resistance,

anti rodent and anti termite properties can be offered as option. Compliance to fire performance

standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the

PVC compound and the overall cable design. LSPVC can also be provided upon request.

Physical AND THERMAL PROPERTIES

Temperature range during operation (fixed state): -20°C - +60°C

Temperature range during installation (mobile state): 0°C - +50°C

Minimum bending radius: 10 times the outer diameter for unarmoured cables

20 times the outer diameter for armoured cables

CONSTRUCTION PARAMETERS

Cable Code |

N° of |

Nominal |

Max. Tensile |

Minimum |

Approx. Weight |

|

|

mm |

N |

mm |

kg/km |

MTA-B-2-0-Y |

2 |

7,6 |

250 |

76 |

55 |

MTA-B-4-0-Y |

4 |

7,8 |

250 |

78 |

67 |

MTA-B-6-0-Y |

6 |

8,6 |

400 |

86 |

77 |

MTA-B-8-0-Y |

8 |

8,8 |

400 |

88 |

81 |

MTA-B-12-0-Y |

12 |

9,3 |

400 |

93 |

90 |