| FIREGUARD Flame Retardant Cables | |||

![]() Flame Retardant Instrumentation Cables

Flame Retardant Instrumentation Cables

Flame Retardant Individual and Overall Screened Instrumentation Cables (Multipair)RE-2X(St)Y PiMF |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flame Retardance (Single Vertical |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE |

Reduced Fire Propagation |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Note: Asterisk ** denotes that the standard compliance is optional, depending on the oxygen index of the PVC compound and the cable design.

VOLTAGE RATING

300/500V

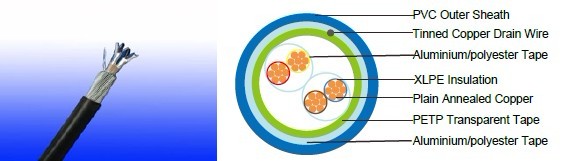

CABLE CONSTRUCTION

Conductor: Annealed or tinned copper, sizes: 0.5mm² and 0.75mm² mulitistranded(Class 5), 0.5

mm², 1.0 mm² solid(Class 1), 1.5mm² or 2.5mm², multistranded(Class 2) to BS6360

Insulation: XLPE (Cross Linked Polyethylene), or PE (optional)

Pairs: Two insulated conductors uniformly twisted together with a lay not exceeding 100mm

Individual Screen: Aluminium/polyester tape is applied over each pair metallic side down in contact

with tinned copper drain wire, 0.5mm²

Binder tape: PETP transparent tape

Overall Screen: Aluminium/polyester tape is applied over the laid up pairs metallic side down in

contact with tinned copper drain wire, 0.5mm²

Outer Sheath: Thermoplastic PVC compound. UV resistance, hydrocarbon resistance, oil resistance,

anti rodent and anti termite properties can be offered as option. Compliance to fire performance

standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the

PVC compound and the overall cable design. LSPVC can also be provided upon request.

COLOUR CODE

Insulation Colour: See technical information

Outer sheath: Black or blue

Physical AND THERMAL PROPERTIES

Maximum Operating temperature: -20˚C - + 90˚C( fixed installation)

0˚C - +50˚C(during operation)

Minimum bending radius: 5 x Overall Diameter

Electrical Properties

Conductor Area Size |

mm 2 |

0.5 |

0.5 |

0.75 |

1.0 |

1.5 |

|

Conductor Stranding |

No. x mm |

1 x 0.8 |

16 x 0.2 |

24 x 0.2 |

1 x 1.13 |

7 x 0.53 |

|

Conductor resistance max |

ohm/km |

36.8 |

39.7 |

26.5 |

18.2 |

12.3 |

|

Insulation resistance min |

Gohm/km |

5 |

5 |

5 |

5 |

5 |

|

Capacitance unbalance at 1 kHz(pair to pair screen) |

pF/250m |

250 |

|||||

Max. Mutual Capacitance @ 1 |

pF/m |

115 |

115 |

115 |

115 |

115 |

|

Max. Mutual Capacitance @ |

pF/m |

75 |

75 |

75 |

75 |

75 |

|

Max. L/R Ratio for adjacent cores(Inductance/Resistance) |

μH/ohm |

25 |

25 |

25 |

25 |

40 |

|

Test voltage |

Core to core |

V |

1000 |

1000 |

1000 |

1000 |

1000 |

Core to screen |

V |

1000 |

1000 |

1000 |

1000 |

1000 |

|

Rated voltage max |

V |

300/500 |

300/500 |

300/500 |

300/500 |

300/500 |

|

CONSTRUCTION PARAMETERS

Number of Pairs |

No./ |

Nominal Conductor Cross- Section Area |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Approx. Weight |

No./mm |

mm2 |

mm |

mm |

mm |

kg/km |

|

2 |

1/0.8 |

0.5 |

0.5 |

0.9 |

9.7 |

95 |

5 |

1/0.8 |

0.5 |

0.5 |

1.2 |

13 |

180 |

10 |

1/0.8 |

0.5 |

0.5 |

1.2 |

16.9 |

310 |

15 |

1/0.8 |

0.5 |

0.5 |

1.3 |

19.7 |

440 |

20 |

1/0.8 |

0.5 |

0.5 |

1.3 |

22.3 |

560 |

30 |

1/0.8 |

0.5 |

0.5 |

1.5 |

27.1 |

820 |

50 |

1/0.8 |

0.5 |

0.5 |

2 |

35 |

1370 |

2 |

16/0.2 |

0.5 |

0.6 |

1.1 |

11.2 |

110 |

5 |

16/0.2 |

0.5 |

0.6 |

1.2 |

14.5 |

250 |

10 |

16/0.2 |

0.5 |

0.6 |

1.3 |

19.3 |

480 |

15 |

16/0.2 |

0.5 |

0.6 |

1.5 |

22.6 |

570 |

20 |

16/0.2 |

0.5 |

0.6 |

1.5 |

25.7 |

780 |

30 |

16/0.2 |

0.5 |

0.6 |

1.7 |

31 |

1020 |

50 |

16/0.2 |

0.5 |

0.6 |

2.2 |

39.9 |

1680 |

2 |

1/1.13 |

1 |

0.6 |

1.1 |

11.9 |

200 |

5 |

1/1.13 |

1 |

0.6 |

1.2 |

15.4 |

290 |

10 |

1/1.13 |

1 |

0.6 |

1.3 |

20.5 |

580 |

15 |

1/1.13 |

1 |

0.6 |

1.5 |

24.1 |

780 |

20 |

1/1.13 |

1 |

0.6 |

1.7 |

27.7 |

1010 |

30 |

1/1.13 |

1 |

0.6 |

2 |

33.7 |

1430 |

50 |

1/1.13 |

1 |

0.6 |

2.2 |

42.5 |

2360 |

2 |

7/0.53 |

1.5 |

0.6 |

1.2 |

13.6 |

250 |

5 |

7/0.53 |

1.5 |

0.6 |

1.3 |

17.7 |

460 |

10 |

7/0.53 |

1.5 |

0.6 |

1.5 |

23.9 |

760 |

15 |

7/0.53 |

1.5 |

0.6 |

1.7 |

28 |

1020 |

20 |

7/0.53 |

1.5 |

0.6 |

2 |

31.7 |

1350 |

30 |

7/0.53 |

1.5 |

0.6 |

2.2 |

38.6 |

1900 |

50 |

7/0.53 |

1.5 |

0.6 |

2.2 |

48.9 |

3060 |