| Industrial Cables | |||

Industrial Cables

Industrial Cables

(H)03Z1Z1-F/(H)05Z1Z1-F

Application and Description

(H)03Z1Z1-F/(H)05Z1Z1-F cables may be used when halogen-free, low smoke and corrosive gas properties are required

in case of fire. For moderate demands in the house, kitchen and office, for house equipment in

damp rooms (for example: washing machines, dryers and refrigerators). Suitable for cooking and

heating equipment, providing that the cable is not in contact with hot components or heat radiation.

Not suitable for use in high temperature areas (like in lighting equipment), outside buildings, in industrial or

agricultural buildings, connection of electrical power tools.

Standard and Approval

<HAR> HD21.14 S1, VDE-0281 Part-14, VDE 0482-332-1-2, CEI 20-20/14, CEI 20-35 (EN60332-1), CEI 2037 (EN50267), EN50363, CE low voltage directive 73/23/EEC & 93/68/EEC, ROHS compliant

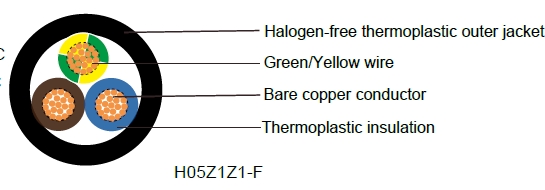

Cable Construction

Fine bare copper strands

Strands to DIN VDE 0295 cl. 5, BS 6360 cl. 5, IEC 60228 cl. 5, HD 383

Thermoplastic TI6 core insulation

Color code VDE-0293-308

Green-yellow grounding (3 conductors and above)

Halogen-fee thermoplastic TM7 outer jacket

Black (RAL 9005) or White (RAL 9003)

Technical Characteristics

Working voltage: 300/300 volts(H03Z1Z1-F), 300/500 volts(H05Z1Z1-F)

Test voltage: 2000 volts(H03Z1Z1-F), 2500 volts(H05Z1Z1-F)

Flexing bending radius: 7.5 x Ø

Fixed bending radius: 4.0 x Ø

Flexing Temperature: -5º C to +70º C

Fixed Temperature: -40º C to +70º C

Short circuit temperature: +160º C

Insulation resistance: 20 MΩ x km

Smoke density acc. to EN 50268 / IEC 61034

Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

Flame test: flame-retardant acc. to EN 50265-2-1, IEC 60332.1

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/Km |

Nominal Weight kg/Km |

(H)03 Z1Z1-F |

||||||

20(16/32) |

2 x 0. 5 |

0.5 |

0.6 |

5.0 |

9.6 |

39 |

20(16/32) |

3 x 0. 5 |

0.5 |

0.6 |

5.3 |

14.4 |

46 |

20(16/32) |

4 x 0. 5 |

0.5 |

0.6 |

5.8 |

19.2 |

56 |

18(24/32) |

2 x 0.75 |

0.5 |

0.6 |

5.4 |

14.4 |

47 |

18(24/32) |

3 x 0.75 |

0.5 |

0.6 |

5.7 |

21.6 |

55 |

18(24/32) |

4 x 0.75 |

0.5 |

0.6 |

6.3 |

29.0 |

69 |

(H)05 Z1Z1-F |

||||||

18(24/32) |

2 x 0.75 |

0.6 |

0.8 |

6.2 |

14.4 |

58 |

18(24/32) |

3 x 0.75 |

0..7 |

0.8 |

6.6 |

21.6 |

68 |

18(24/32) |

4 x 0.75 |

0.8 |

0.8 |

7.1 |

29 |

81 |

18(24/32) |

5 x 0.75 |

0.8 |

0.9 |

8 |

36 |

102 |

17(32/32) |

2 x 1 |

0.6 |

0.8 |

6.6 |

19 |

67 |

17(32/32) |

3 x 1 |

0.8 |

0.8 |

6.9 |

29 |

81 |

17(32/32) |

4 x 1 |

0.8 |

0.9 |

7.7 |

38 |

101 |

17(32/32) |

5 x 1 |

0.8 |

0.9 |

8.4 |

48 |

107 |

16(30/30) |

2 x 1.5 |

0..7 |

0.8 |

7.4 |

29 |

87 |

16(30/30) |

3 x 1.5 |

0.8 |

0.9 |

8.1 |

43 |

109 |

16(30/30) |

4 x 1.5 |

0.8 |

1.0 |

9 |

58 |

117 |

16(30/30) |

5 x 1.5 |

0.8 |

1.1 |

10 |

72 |

169 |

14(50/30) |

2 x 2.5 |

0.8 |

1.0 |

9.3 |

48 |

138 |

14(50/30) |

3 x 2.5 |

1.0 |

1.1 |

10.1 |

72 |

172 |

14(50/30) |

4 x 2.5 |

1.0 |

1.1 |

11 |

96 |

210 |

14(50/30) |

5 x 2.5 |

1.0 |

1.2 |

12.3 |

120 |

260 |

12(56/28) |

2 x 4 |

0.8 |

1.1 |

10.6 |

76.8 |

190 |

12(56/28) |

3 x 4 |

1.0 |

1.2 |

11.5 |

115.2 |

242 |

12(56/28) |

4 x 4 |

1.0 |

1.4 |

12.5 |

153.6 |

298 |

12(56/28) |

5 x 4 |

1.0 |

1.4 |

14.1 |

192 |

371 |