| Industrial Cables | |||

Industrial Cables Multi-Core Flexible Cables

Industrial Cables Multi-Core Flexible Cables

309Y to BS 6500

Application and Description

309Y to BS 6500 cables are suitable for domestic premises, kitchen, office for light service or light portable

apparatuses. With their special insulation and sheath compounds, these cables are adapted for

apparatus in kitchen and heating and for use in zones with high temperature (like lighting system

apparatuses) without contact with warm parts and radiations. Unsuitable for outdoor use, in industrial

and agricultural buildings or non-domestic portable tools. 309Y is equivalent to harmonized code

H05V2V2-F.

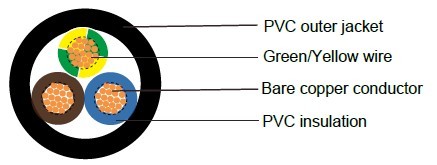

Cable Construction

Bare copper fine wire conductor

Stranding to BS Class 5 or IEC 60228 Class 5

PVC core insulation TI3 to BS 7655

Green/Yellow grounding (3 conductors and above)

PVC outer jacket TM3 to BS 7655

Core Identification

2 Cores: Blue, Brown

3 Cores: Green/Yellow, Blue, Brown

4 Cores: Green/Yellow, Brown, Black, Grey

5 Cores: Green/Yellow, Brown, Black, Grey, Blue

Technical Characteristics

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 15xOverall diameter

Static bending radius: 4xOverall diameter

Flexing temperature: +5º C to +90º C

Static temperature: -40º C to +90º C

Short circuit temperature: +160º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩxkm

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| 3092Y | ||||||

| 20(16/32) | 2x0.50 | 0.6 | 0.8 | 5.6-7 | 14.4 | 46 |

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 6-7.6 | 14.4 | 56 |

| 17(32/32) | 2x1.00 | 0.6 | 0.8 | 6.4-8 | 19 | 65 |

| 16(30/30) | 2x1.50 | 0.7 | 0.8 | 7.4-9 | 29 | 80 |

| 14(30/50) | 2x2.50 | 0.8 | 1.0 | 8.9-11 | 48 | 135 |

| 3093Y | ||||||

| 20(16/32) | 3x0.50 | 0.6 | 0.8 | 5.8-7.2 | 14.4 | 56 |

| 18(24/32) | 3x0.75 | 0.6 | 0.8 | 6.4-8 | 21.6 | 61 |

| 17(32/32) | 3x1.00 | 0.6 | 0.8 | 6.8-8.4 | 29 | 77 |

| 16(30/30) | 3x1.50 | 0.7 | 0.9 | 8-9.8 | 43 | 108 |

| 14(30/50) | 3x2.50 | 0.8 | 1.1 | 9.6-12 | 72 | 165 |

| 12(56/28) | 3x40 | 0.8 | 1.2 | 10.8-13.1 | 115 | 224 |

| 3094Y | ||||||

| 20(16/32) | 4x0.50 | 0.6 | 0.8 | 6.4-7.8 | 14.4 | 68 |

| 18(24/32) | 4x0.75 | 0.6 | 0.8 | 6.8-8.6 | 29 | 80 |

| 17(32/32) | 4x1.00 | 0.6 | 0.9 | 7.6-9.4 | 38 | 100 |

| 16(30/30) | 4x1.50 | 0.7 | 1.0 | 9-11 | 58 | 140 |

| 14(30/50) | 4x2.50 | 0.8 | 1.1 | 10.5-13 | 96 | 210 |

| 12(56/28) | 4x40 | 0.8 | 1.2 | 11.8-14.1 | 154 | 295 |

| 3095Y | ||||||

| 18(24/32) | 5x0.75 | 0.6 | 0.9 | 7.4-9.6 | 36 | 110 |

| 17(32/32) | 5x1.00 | 0.6 | 0.9 | 8.3-10 | 48 | 130 |

| 16(30/30) | 5x1.50 | 0.7 | 1.1 | 10-12 | 72 | 185 |

| 14(30/50) | 5x2.50 | 0.8 | 1.2 | 11.5-14 | 120 | 265 |

| 12(56/28) | 5x40 | 0.8 | 1.4 | 13.1-16.3 | 192 | 361 |