| Industrial Cables | |||

Industrial Cables Multi-Core Flexible Cables

Industrial Cables Multi-Core Flexible Cables

318TQ to BS 6500

Application and Description

318TQ to BS 6500 cables can be used either in dry, humid or wet places or in contact with oil or grease, in weather

conditions and under weak mechanical stress, they are suitable for power supply to small appliances in

industrial plants, machine shops, heating plates, portable lamps, farming equipment etc. They are also

suitable for caravans and camping equipment. 318TQ is equivalent to harmonized code H05BN4-F.

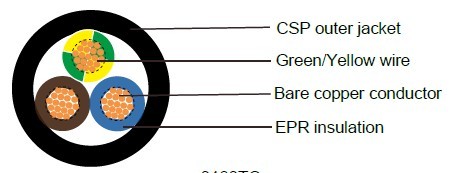

Cable Construction

Fine bare copper strands

Stranding to BS 6360 Class 5 or IEC 60228 Class 5

EPR(Ethylene Propylene Rubber) rubber EI7 insulation

CSP(Chlorosulphonated Polyethylene) outer jacket EM7

Core Identification

2 cores: Brown, Blue

3 cores: Green/Yellow, Brown, Blue

4 cores: Green/Yellow, Brown, Black, Grey

5 cores: Green/Yellow, Blue, Brown, Black, Grey

6 cores and above: white insulation with black numerals

Technical Characteristics

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 6xOverall diameter

Fixed bending radius: 4xOverall diameter

Temperature Range: -20º C to +90º C

Maximum short circuit temperature: +250º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩxkm

Cable Parameter

| AWG (No of Strands/ Strand Diameter) | No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 3181TQ | |||||

| 20(16/32) | 1x0.5 | 0.6 | 0.8 | 3.8 | 19 |

| 18(24/32) | 1x0.75 | 0.6 | 0.8 | 4 | 23 |

| 17(32/32) | 1x1 | 0.6 | 0.8 | 4.2 | 28 |

| 16(30/30) | 1x1.5 | 0.8 | 0.8 | 4.9 | 38 |

| 14(50/30) | 1x2.5 | 0.9 | 0.8 | 5.5 | 41 |

| 12(56/28) | 1x4 | 1 | 0.8 | 6.3 | 73 |

| 3182TQ | |||||

| 20(16/32) | 2x0.5 | 0.6 | 0.8 | 6.1 | 59 |

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 6.5 | 66 |

| 17(32/32) | 2x1 | 0.6 | 0.9 | 7.1 | 79 |

| 16(30/30) | 2x1.5 | 0.8 | 1 | 8.7 | 120 |

| 14(50/30) | 2x2.5 | 0.9 | 1.1 | 10.1 | 170 |

| 12(56/28) | 2x4 | 1 | 1.2 | 11.9 | 235 |

| 3183TQ | |||||

| 20(16/32) | 3x0.5 | 0.6 | 0.8 | 6.5 | 65 |

| 18(24/32) | 3x0.75 | 0.6 | 0.9 | 7.1 | 80 |

| 17(32/32) | 3x1 | 0.6 | 0.9 | 7.6 | 94 |

| 16(30/30) | 3x1.5 | 0.8 | 1 | 9.3 | 140 |

| 14(50/30) | 3x2.5 | 0.9 | 1.1 | 10.8 | 200 |

| 12(56/28) | 3x4 | 1 | 1.2 | 12.7 | 285 |

| 3184TQ | |||||

| 18(24/32) | 4x0.75 | 0.6 | 0.9 | 7.7 | 96 |

| 17(32/32) | 4x1 | 0.6 | 0.9 | 8.2 | 113 |

| 16(30/30) | 4x1.5 | 0.8 | 1.1 | 10.3 | 174 |

| 14(50/30) | 4x2.5 | 0.9 | 1.2 | 12 | 252 |

| 12(56/28) | 4x4 | 1 | 1.3 | 14.1 | 355 |

| 3185TQ | |||||

| 18(24/32) | 5x0.75 | 0.6 | 1 | 8.6 | 115 |

| 17(32/32) | 5x1 | 0.6 | 1 | 9.2 | 140 |

| 16(30/30) | 5x1.5 | 0.8 | 1.2 | 11.5 | 195 |

| 14(50/30) | 5x2.5 | 0.9 | 1.2 | 13.1 | 290 |

| 12(56/28) | 5x4 | 1 | 1.3 | 15.4 | 417 |

| 3186TQ | |||||

| 18(24/32) | 6x0.75 | 0.6 | 1.1 | 9.6 | 135 |

| 17(32/32) | 6x1 | 0.6 | 1.1 | 10.2 | 171 |

| 16(30/30) | 6x1.5 | 0.8 | 1.3 | 12.7 | 235 |

| 14(50/30) | 6x2.5 | 0.9 | 1.4 | 14.7 | 340 |

| 3187TQ | |||||

| 18(24/32) | 7x0.75 | 0.6 | 1.1 | 10.4 | 170 |

| 17(32/32) | 7x1 | 0.6 | 1.1 | 11.1 | 201 |

| 16(30/30) | 7x1.5 | 0.8 | 1.2 | 13.6 | 366 |

| 14(50/30) | 7x2.5 | 0.9 | 1.3 | 15.8 | 424 |

| 3188TQ | |||||

| 18(24/32) | 8x0.75 | 0.6 | 1.2 | 11.3 | 175 |

| 17(32/32) | 8x1 | 0.6 | 1.3 | 12.3 | 244 |

| 16(30/30) | 8x1.5 | 0.8 | 1.5 | 15.2 | 315 |

| 14(50/30) | 8x2.5 | 0.9 | 1.7 | 17.8 | 465 |

| 3189TQ | |||||

| 18(24/32) | 9x0.75 | 0.6 | 1.3 | 12.4 | 201 |

| 17(32/32) | 9x1 | 0.6 | 1.3 | 13.2 | 268 |

| 16(30/30) | 9x1.5 | 0.8 | 1.6 | 16.6 | 333 |

| 14(50/30) | 9x2.5 | 0.9 | 1.8 | 119.4 | 490 |

| 31810TQ | |||||

| 18(24/32) | 10x0.75 | 0.6 | 1.3 | 12.4 | 215 |

| 17(32/32) | 10x1 | 0.6 | 1.3 | 13.2 | 286 |

| 16(30/30) | 10x1.5 | 0.8 | 1.6 | 16.6 | 360 |

| 14(50/30) | 10x2.5 | 0.9 | 1.8 | 19.4 | 530 |