| Industrial Cables | |||

Industrial Cables Multi-Core Flexible Cables

Industrial Cables Multi-Core Flexible Cables

318Y to BS 6500

Application and Description

318Y to BS 6500 cables are suited for medium mechanical stress in damp and wet environments such as

refrigerators, washing machines, spin dryers and other appliances, as long as it meets applicable

equipment specifications.318Y to BS 6500 cables are also suited for cooking and heating apparatus, provided

that the cable does not come into direct contact with the hot parts of the apparatus or with any other

heat source. Further applications of this cable include: Fixed installation in furniture, partition walls,

decorative covering, and in the hollow spaces of prefabricated building parts. They are not suitable

for outdoor use, industrial (except clothing manufacture) or farming applications. 318Y is equivalent to

harmonized code H05VV-F.

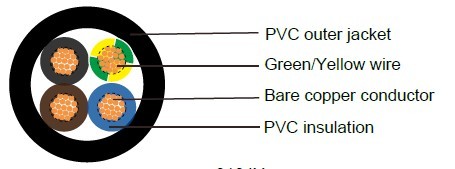

Cable Construction

Bare copper fine wire conductor

Stranding to BS 6360 Class 5 or IEC 60228 Class 5

PVC core insulation TI2 to BS 7655

Green/Yellow grounding (3 conductors and above)

PVC outer jacket TM2 to BS 7655

Core Identification

2 Cores: Blue, Brown

3 Cores: Green/Yellow, Blue, Brown

4 Cores: Green/Yellow, Brown, Black, Grey

5 Cores: Green/Yellow, Brown, Black, Grey, Blue

Technical Characteristics

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 7.5xOverall diameter

Static bending radius: 4xOverall diameter

Flexing temperature: -5º C to +70º C

Static temperature: -40º C to +70º C

Short circuit temperature: +160º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩxkm

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| 3182Y | ||||||

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 6.4 | 14.4 | 57 |

| 17(32/32) | 2x1.00 | 0.6 | 0.8 | 6.8 | 19 | 65 |

| 16(30/30) | 2x1.50 | 0.7 | 0.8 | 7.6 | 29 | 87 |

| 14(30/50) | 2x2.50 | 0.8 | 1.0 | 9.2 | 48 | 134 |

| 12(56/28) | 2x40 | 0.8 | 1.1 | 10.5 | 77 | 174 |

| 3183Y | ||||||

| 18(24/32) | 3x0.75 | 0.6 | 0.8 | 6.8 | 21.6 | 68 |

| 17(32/32) | 3x1.00 | 0.6 | 0.8 | 7.2 | 29 | 79 |

| 16(30/30) | 3x1.50 | 0.7 | 0.9 | 8.2 | 43 | 111 |

| 14(30/50) | 3x2.50 | 0.8 | 1.1 | 10.1 | 72 | 169 |

| 12(56/28) | 3x40 | 0.8 | 1.2 | 11.3 | 115 | 233 |

| 3184Y | ||||||

| 18(24/32) | 4x0.75 | 0.6 | 0.8 | 7.4 | 29 | 84 |

| 17(32/32) | 4x1.00 | 0.6 | 0.9 | 8.0 | 38 | 101 |

| 16(30/30) | 4x1.50 | 0.7 | 1.0 | 9.2 | 58 | 142 |

| 14(30/50) | 4x2.50 | 0.8 | 1.1 | 11.2 | 96 | 211 |

| 12(56/28) | 4x4.0 | 0.8 | 1.2 | 12.5 | 154 | 292 |

| 3185Y | ||||||

| 18(24/32) | 5x0.75 | 0.6 | 0.9 | 8.5 | 36 | 106 |

| 17(32/32) | 5x1.00 | 0.6 | 0.9 | 8.8 | 48 | 123 |

| 16(30/30) | 5x1.50 | 0.7 | 1.1 | 10.5 | 72 | 176 |

| 14(30/50) | 5x2.50 | 0.8 | 1.2 | 12.4 | 120 | 262 |

| 12(56/28) | 5x4.0 | 0.8 | 1.4 | 13.7 | 192 | 369 |