| Industrial Cables | |||

Industrial Cables Single Core Fixed Wiring Cable

Industrial Cables Single Core Fixed Wiring Cable

6181B to BS 7889

Application and Description

6181B to BS 7889e cables are designed for fixed wiring purposes in domestic and

industrial power/lighting applications. They can be installed in trunking

or conduit, or may be surface mounted when used for earthing. 6181B to BS 7889 cables are

suitable for use in areas (such as public and government buildings) where

smoke and toxic fumes may cause a threat to life and equipment. When

mechanical protection is required, they can be embedded in concrete.

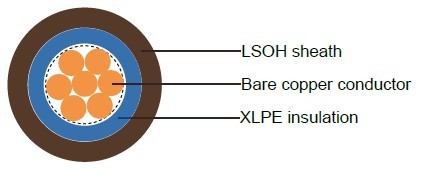

Cable Construction

Bare copper made of strands conductor

Stranding to IEC 60228 Class 2

XLPE insulation

LSOH sheath

Core Identification

Black, Blue, Brown

Technical Characteristics

Working voltage: 600/1000 volts

Minimum bending radius: up to 25 mm² 4xoverall diameter,

above 25 mm² 6xoverall diameter

Operating temperature: -15º C to +90º C

Insulation resistance: 10 MΩxkm

Halogen free acc. to EN 50267-2-1 / IEC 60754-1

Smoke density acc. to EN 50268-2 / IEC 61034-2

Corrosivity of gases acc. to EN 50267-2-2, IEC 60754-2

Flame retardancy acc. to EN 50265-2-1, IEC 60332-1

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 16(1/16) | 1x1.5 | 0.7 | 1.4 | 6 | 50 |

| 14(1/14) | 1x2.5 | 0.7 | 1.4 | 6.5 | 70 |

| 12(7/20) | 1x4 | 0.7 | 1.4 | 7 | 80 |

| 10(7/18) | 1x6 | 0.7 | 1.4 | 7.5 | 110 |

| 8(7/16) | 1x10 | 0.7 | 1.4 | 8.5 | 150 |

| 6(7/14) | 1x16 | 0.7 | 1.4 | 9.5 | 215 |

| 4(7/12) | 1x25 | 0.9 | 1.4 | 11.5 | 315 |

| 2(7/10) | 1x35 | 0.9 | 1.4 | 12 | 415 |

| 1(19/13) | 1x50 | 1 | 1.4 | 13 | 555 |

| 2/0(19/11) | 1x70 | 1.1 | 1.4 | 15 | 760 |

| 3/0(19/10) | 1x95 | 1.1 | 1.5 | 17 | 1025 |

| 4/0(37/12) | 1x120 | 1.2 | 1.5 | 18.5 | 1270 |

| 300MCM(37/11) | 1x150 | 1.4 | 1.6 | 21.5 | 1575 |

| 350MCM(37/10) | 1x185 | 1.6 | 1.6 | 23 | 1955 |

| 500MCM(61/11) | 1x240 | 1.7 | 1.7 | 26 | 2470 |

| (61/10) | 1x300 | 1.8 | 1.8 | 28 | 3155 |

| (61/9) | 1x400 | 2 | 1.9 | 32 | 4049 |

| (61/8) | 1x500 | 2.2 | 2 | 36 | 5100 |

| (127/10) | 1x630 | 2.4 | 2.2 | 40 | 6410 |