| Industrial Cables | |||

Industrial Cables Multi-Core Flexible Cables

Industrial Cables Multi-Core Flexible Cables

6241B/6242B/ 6243B to BS 7211

Application and Description

6241B/6242B/ 6243B to BS 7211 cables are suitable for fixed installation particularly for situations in which low emission smoke

and domestic wiring cable for the surface wiring of sockets and lighting where fire, smoke emission and

toxic fumes create a potential threat to life and equipment. Can be installed in fixed installations in dry

or damp premises on walls, boards or trays, in channels or embedded in plaster. Suitable for laying in

conduit or trunking where mechanical protection is required.

Cable Construction

Fine bare copper strands

Stranding to IEC 60228 Class 1 or 2

Thermosetting core insulation type EI5 or GP 8

The core or cores shall be laid parallel with the uninsulated circuit protective conductor

For twin cores, the protective conductor centrally placed between cores in same plane

For 3 cores, the protective conductor centrally placed between black and grey cores in same plane

LSOH sheath, type LTS 2, white

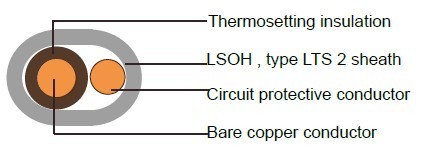

6241B

6241B

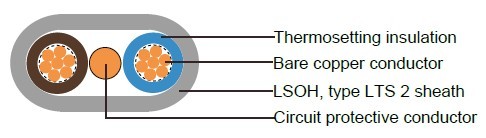

6242B

6242B

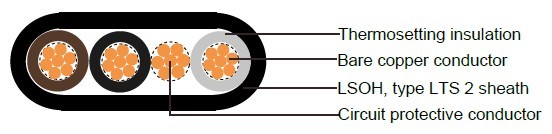

6243B

6243B

Core Identification

2 cores: brown and blue, or, for 2 × 1.0 and 2 × 1.5 cables, brown and brown

3 cores: brown, black (centre core) and grey

Technical Characteristics

Working voltage: 300/500v

Test voltage: 2000 volts

Flexing bending radius: 15xOverall diameter

Static bending radius: 10xOverall diameter

Flexing temperature: +5º C to +90º C

Short circuit temperature: +250º C

Insulation resistance: 10 MΩxkm

Halogen free acc. to EN 50267-2-1 / IEC 60754-1

Smoke density acc. to EN 50268-2 / IEC 61034-2

Corrosivity of gases acc. to EN 50267-2-2, IEC 60754-2

Flame retardancy acc. to EN 50265-2-1, IEC 60332-1

Cable Parameter

| AWG (No of Strands/ Strand Diameter) | No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal thickness of insulation mm |

Nominal thickness of sheath mm |

Nominal overall dimensions | Circuit protective conductor AWG | Nominal Weight kg/km | |

| lower limit mm |

upper limit mm |

||||||

| 6241B | |||||||

| 17 | 1 × 1.0 | 0.7 | 0.9 | 4.1 × 5.2 | 5.0 × 6.3 | 17 | 45 |

| 16 | 1 × 1.5 | 0.7 | 0.9 | 4.4 × 5.4 | 5.3 × 6.6 | 17 | 55 |

| 6242B | |||||||

| 17 | 2 × 1.0 | 0.7 | 0.9 | 4.1 × 7.6 | 5.0 × 9.1 | 17 | 68 |

| 17(7/26) | 2 × 1.0 | 0.7 | 0.9 | 4.2 × 7.8 | 5.1 × 9.4 | 17 | 73 |

| 16 | 2 × 1.5 | 0.7 | 0.9 | 4.4 × 8.1 | 5.3 × 9.7 | 17 | 85 |

| 16(7/24) | 2 × 1.5 | 0.7 | 0.9 | 4.5 × 8.3 | 5.4 × 10 | 17 | 90 |

| 14 | 2 × 2.5 | 0.7 | 1.0 | 4.9 × 9.3 | 6 × 11.2 | 16 | 120 |

| 14(7/22) | 2 × 2.5 | 0.7 | 1.0 | 5.0 × 9.5 | 6.1 × 11.4 | 16 | 125 |

| 12(7/20) | 2 × 4 | 0.7 | 1.0 | 5.5 × 10.4 | 6.7 × 12.6 | 16 | 175 |

| 10(7/18) | 2 × 6 | 0.7 | 1.1 | 6.2 × 12.0 | 7.5 × 14.6 | 14 | 240 |

| 8(7/16) | 2 × 10 | 0.7 | 1.2 | 7.3 × 14.5 | 8.8 × 17.6 | 12(7/20) | 390 |

| 6(7/14) | 2 × 16 | 0.7 | 1.3 | 8.4 × 17.0 | 10.1 × 20.5 | 10(7/18) | 560 |

| 6243B | |||||||

| 17 | 3 × 1.0 | 0.7 | 0.9 | 4.1 × 10 | 5.1 × 12.1 | 17 | 91 |

| 16 | 3 × 1.5 | 0.7 | 0.9 | 4.4 × 10.7 | 5.3 × 12.9 | 17 | 115 |

| 14 | 3 × 2.5 | 0.7 | 1.0 | 4.9 × 12.0 | 6 × 14.6 | 17 | 170 |

| 12(7/20) | 3 × 4 | 0.7 | 1.0 | 5.5 × 14 | 6.7 × 16.9 | 16 | 196 |

| 10(7/18) | 3 × 6 | 0.7 | 1.1 | 6.2 × 16.2 | 7.5 × 19.5 | 14 | 291 |

| 8(7/16) | 3 × 10 | 0.7 | 1.2 | 7.3 × 19.5 | 8.8 × 23.6 | 12(7/20) | 440 |

| 6(7/14) | 3 × 16 | 0.7 | 1.3 | 8.4 × 22.8 | 10.1 × 27.6 | 10(7/18) | 670 |