| Industrial Cables | |||

Industrial Cables

Industrial Cables

FFG7OR

Application and Description

FFG7OR cables are suitable for power transport in industry, yards, residential building and handicraft. For installations on masonry and metal structures, on gangways, pipes, ducts and similar systems. For fixed installation indoors and outdoors. Underground laying is acceptable, even if not protected.

Standard and Approval

CEI 20-13

CEI 20-22/2

CEI 20-35 (EN60332-1)

CEI 20-37 pt.2 (EN50267)

CEI 20-52

Low Voltage Directive 73/23/EEC

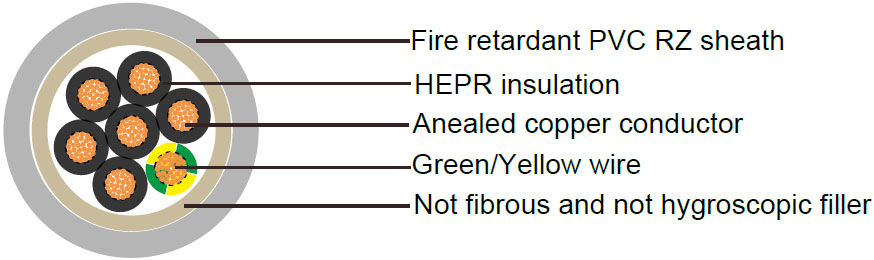

Cable Construction

| Flexible conductor of annealed red copper Cl.6 |

| Rubber HEPR, G7 quality,acc. to CEI 20-11 CEI 20-3 |

| Not fibrous and not hygroscopic filler |

| Grey PVC RZ quality outer jacket |

Technical Characteristics

| Working voltage | 600/1000 V |

| Test voltage | 4000 V |

| Minimum bending radius | 4.0 x Ø |

| Flexing temperature | 0°C to +90º C |

| Static temperature | -25°C to +90º C |

| Maximum short circuit temperature | +250ºC |

| Flame retardant | CEI 20-22 II |

| Insulation resistance | 20 MΩ x km |

Cable Parameter

| AWG | No. of Cores x Nominal Cross Sectional Area | Nominal Thickness of Insulation | Nominal Thickness of Sheath | Nominal Overall Diameter | Nominal Weight |

| # x mm² | mm | mm | mm | kg/km | |

| power | |||||

| 16(30/30) | 1 x 1.5 | 0.7 | 1.4 | 6.3 | 49 |

| 14(50/30) | 1 x 2.5 | 0.7 | 1.4 | 6.9 | 60 |

| 12(56/28) | 1 x 4 | 0.7 | 1.4 | 7.6 | 80 |

| 10(84/28) | 1 x 6 | 0.7 | 1.4 | 8.2 | 102 |

| 8(80/26) | 1 x 10 | 0.7 | 1.4 | 9.0 | 147 |

| 6(128/26) | 1 x 16 | 0.7 | 1.4 | 10.1 | 206 |

| 4(200/26) | 1 x 25 | 0.9 | 1.4 | 11.2 | 290 |

| 2(280/26) | 1 x 35 | 0.9 | 1.4 | 12.2 | 390 |

| 1(400/26) | 1 x 50 | 1 | 1.4 | 13.9 | 530 |

| 2/0(356/24) | 1 x 70 | 1.1 | 1.4 | 16.0 | 720 |

| 3/0(485/24) | 1 x 95 | 1.1 | 1.5 | 17.7 | 940 |

| 4/0(614/24) | 1 x 120 | 1.2 | 1.5 | 19.7 | 1200 |

| 250MCM | 1 x 150 | 1.4 | 1.6 | 21.8 | 1480 |

| 350MCM | 1 x 185 | 1.6 | 1.6 | 23.9 | 1800 |

| 450MCM | 1 x 240 | 1.7 | 1.7 | 26.4 | 2330 |

| 550MCM | 1 x 300 | 1.8 | 1.8 | 28.9 | 3050 |

| 750MCM | 1 x 400 | 2.0 | 1.9 | 35.0 | 4000 |

| 1000MCM | 1 x 500 | 2.2 | 2.1 | 39.5 | 5020 |

| 1250MCM | 1 x 630 | 2.4 | 2.2 | 44.0 | 6600 |

| 16(30/30) | 2 x 1.5 | 0.7 | 1.8 | 12 | 150 |

| 14(50/30) | 2 x 2.5 | 0.7 | 1.8 | 13 | 185 |

| 12(56/28) | 2 x 4 | 0.7 | 1.8 | 14.2 | 238 |

| 10(84/28) | 2 x 6 | 0.7 | 1.8 | 15.4 | 304 |

| 8(80/26) | 2 x 10 | 0.7 | 1.8 | 19.2 | 435 |

| 6(128/26) | 2 x 16 | 0.7 | 1.8 | 20.4 | 590 |

| 4(200/26) | 2 x 25 | 0.9 | 1.8 | 24.5 | 830 |

| 2(280/26) | 2 x 35 | 0.9 | 1.8 | 26.6 | 1100 |

| 1(400/26) | 2 x 50 | 1 | 1.8 | 30 | 1500 |

| 16(30/30) | 3 x 1.5 | 0.7 | 1.8 | 12.5 | 165 |

| 14(50/30) | 3 x 2.5 | 0.7 | 1.8 | 13.6 | 210 |

| 12(56/28) | 3 x 4 | 0.7 | 1.8 | 14.9 | 275 |

| 10(84/28) | 3 x 6 | 0.7 | 1.8 | 16.2 | 355 |

| 8(80/26) | 3 x 10 | 0.7 | 1.8 | 19.3 | 515 |

| 6(128/26) | 3 x 16 | 0.7 | 1.8 | 21.6 | 730 |

| 4(200/26) | 3 x 25 | 0.9 | 1.8 | 26 | 1040 |

| 2(280/26) | 3 x 35 | 0.9 | 1.8 | 28.3 | 1370 |

| 1(400/26) | 3 x 50 | 1 | 1.8 | 31.9 | 1875 |

| 2/0(356/24) | 3 x 70 | 1.1 | 1.9 | 37.4 | 2610 |

| 3/0(485/24) | 3 x 95 | 1.1 | 2 | 42.2 | 3340 |

| 4/0(614/24) | 3 x 120 | 1.2 | 2.1 | 46.7 | 4320 |

| 300MCM | 3 x 150 | 1.4 | 2.3 | 51.1 | 5300 |

| 3 x 35 + 25 | 0.9 | 1.8 | 30.5 | 1600 | |

| 3 x 50 + 25 | 1 | 1.8 | 33.7 | 2210 | |

| 3 x 70+ 35 | 1.1 | 1.9 | 38.8 | 3050 | |

| 3 x 95 + 50 | 1.1 | 2.1 | 43.9 | 3800 | |

| 3 x 120 + 70 | 1.2 | 2.2 | 49.3 | 5000 | |

| 3 x 150 + 95 | 1.4 | 2.4 | 54.4 | 6350 | |

| 16(30/30) | 4 x 1.5 | 0.7 | 1.8 | 13.4 | 190 |

| 14(50/30) | 4 x 2.5 | 0.7 | 1.8 | 14.5 | 245 |

| 12(56/28) | 4 x 4 | 0.7 | 1.8 | 16.1 | 325 |

| 10(84/28) | 4 x 6 | 0.7 | 1.8 | 17.5 | 425 |

| 8(80/26) | 4 x 10 | 0.7 | 1.8 | 21 | 625 |

| 6(128/26) | 4 x 16 | 0.7 | 1.8 | 23.5 | 890 |

| 4(200/26) | 4 x 25 | 0.9 | 1.8 | 28.6 | 1300 |

| 16(30/30) | 5 x 1.5 | 0.7 | 1.8 | 14.4 | 217 |

| 14(50/30) | 5 x 2.5 | 0.7 | 1.8 | 15.6 | 283 |

| 12(56/28) | 5 x 4 | 0.7 | 1.8 | 17.3 | 378 |

| 10(84/28) | 5 x 6 | 0.7 | 1.8 | 18.8 | 500 |

| 8(80/26) | 5 x 10 | 0.7 | 1.8 | 22.8 | 740 |

| 6(128/26) | 5 x 16 | 0.7 | 1.8 | 25.7 | 1070 |

| 4(200/26) | 5 x 25 | 0.9 | 1.8 | 31.2 | 1550 |

| 2(280/26) | 5 x 35 | 0.9 | 1.8 | 34.3 | 2050 |

| 1(400/26) | 5 x 50 | 1 | 2 | 39.1 | 2850 |

| control | |||||

| 16(30/30) | 5 x 1.5 | 0.7 | 1.8 | 17.5 | 350 |

| 16(30/30) | 7 x 1.5 | 0.7 | 1.8 | 18.5 | 400 |

| 16(30/30) | 10 x 1.5 | 0.7 | 1.8 | 21.5 | 550 |

| 16(30/30) | 12 x 1.5 | 0.7 | 1.8 | 22.5 | 600 |

| 16(30/30) | 16 x 1.5 | 0.7 | 1.8 | 24.0 | 720 |

| 16(30/30) | 19 x 1.5 | 0.7 | 1.8 | 25.0 | 830 |

| 16(30/30) | 24 x 1.5 | 0.7 | 1.8 | 28.5 | 1050 |

| 14(50/30) | 7 x2.5 | 0.7 | 1.8 | 19.5 | 500 |

| 14(50/30) | 10 x 2.5 | 0.7 | 1.8 | 23.5 | 750 |

| 14(50/30) | 12 x 2.5 | 0.7 | 1.8 | 24.5 | 800 |

| 14(50/30) | 16 x 2.5 | 0.7 | 1.8 | 26.5 | 1000 |

| 14(50/30) | 19 x 2.5 | 0.7 | 1.8 | 28.0 | 1150 |

| 14(50/30) | 24 x 2.5 | 0.7 | 1.8 | 31.5 | 1450 |

* Galvinized steel armouring version (FG7ORAR) is available