| Industrial Cables | |||

Industrial Cables

Industrial Cables

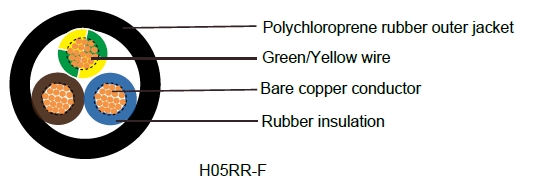

H05RR-F

Application and Description

H05RR-F cables are flexible rubber insulated; rubber jacketed harmonized cord, recommended for use in

equipment, which is subject to light and medium stresses in both dry and damp environments. For use with

electronics and electrical equipment such as appliances, small hand tools and office equipment They can

be found in flat irons, soldering irons, kitchen aids, toasters, stoves and in connections with light commercial

electric tools. Also suitable for fixed installation in furniture, decorative coverings, wall partitions and prefabricated building parts. Max operating voltage in single or three phase system is Uo/U 300/500 volts. In a

direct current system max operating voltage is Uo/U 413/825 volts. Outdoor use is permitted only for a short

time. They are ozone resistant, oil & fat resistant.

Standard and Approval

<HAR> HD22.4 S3, VDE-0282 Part-4, CEI 20-19/4 / 20-35 (EN60332-1),

CE low voltage directive 73/23/EEC & 93/68/EEC., IEC 60245-4, ROHS compliant

Cable Construction

Fine bare copper strands

Strands to VDE-0295 Class-5, IEC 60228 Class-5

Rubber core insulation EI4 to VDE-0282 Part-1

Color code VDE-0293-308 and HD 186

Green-yellow grounding, 3 conductors and above

Polychloroprene rubber (neoprene) jacket EM3

Technical Characteristics

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 8 x Ø

Fixed bending radius: 6 x Ø

Temperature range: -30º C to +60º C

Short circuit temperature: +200 º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩ x km

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # x mm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm min-max |

Nominal Copper Weight kg/Km |

Nominal Weight kg/Km |

18(24/32) |

2 x 0.75 |

0.6 |

0.8 |

5.7-7.4 |

14.4 |

61 |

18(24/32)

|

3 x 0.75 |

0.6 |

0.9 |

6.2-8.1 |

21.6 |

75 |

18(24/32) |

4 x 0.75 |

0.6 |

0.9 |

6.8-8.8 |

28.8 |

94 |

18(24/32)

|

5 x 0.75 |

0.6 |

1.0 |

7.6-9.9 |

36.0 |

110 |

17(32/32) |

2 x 1 |

0.6 |

0.9 |

6.1-8.0 |

19.0 |

73 |

17(32/32)

|

3 x 1 |

0.6 |

0.9 |

6.5-8.5 |

29.0 |

86 |

17(32/32)

|

4 x 1 |

0.6 |

0.9 |

7.1-9.3 |

38.4 |

105 |

17(32/32)

|

5 x 1 |

0.6 |

1.0 |

8.0-10.3 |

48.0 |

130 |

16(30/30) |

2 x 1.5 |

0.8 |

1.0 |

7.6-9.8 |

29.0 |

115 |

16(30/30)

|

3 x 1.5 |

0.8 |

1.0 |

8.0-10.4 |

43.0 |

135 |

16(30/30)

|

4 x 1.5 |

0.8 |

1.1 |

9.0-11.6 |

58.0 |

165 |

16(30/30)

|

5 x 1.5 |

0.8 |

1.1 |

9.8-12.7 |

72.0 |

190 |

14(50/30) |

2 x 2.5 |

0.9 |

1.1 |

9.0-11.6 |

48.0 |

160 |

14(50/30)

|

3 x 2.5 |

0.9 |

1.1 |

9.6-12.4 |

72.0 |

191 |

14(50/30)

|

4 x 2.5 |

0.9 |

1.2 |

10.7-13.8 |

96.0 |

235 |

14(50/30)

|

5 x 2.5 |

0.9 |

1.3 |

11.9-15.3 |

120.0 |

285 |