| Industrial Cables | |||

Industrial Cables

Industrial Cables

H05V2V2-F/H05V2V2H2-F

Application and Description

H05V2V2-F/H05V2V2H2-F cables are suitable for domestic premises, kitchen, office for light service or light portable

apparatuses. With their special insulation and sheath compounds H05V2V2-F/H05V2V2H2-F cables are adapt for apparatus in

kitchen and heating and for use in zones with high temperature (like lighting system apparatuses) without

contact with warm parts and radiations. Unsuitable for outdoor use, in industrial and agricultural buildings

or non-domestic portable tools. The maximum conductor temperature in normal use: 90°C.While high

temperature use, skin contact must be avoided

Standard and Approval

<HAR>HD 21.12; HD 308 S2, DIN VDE 0281 part 1, part 12, DIN VDE 0293 part 308, DIN VDE 0295

CEI 20-20/12, CEI 20-35 (EN60332-1) / CEI 20-37 (EN50267), CENELEC HD 21.12 S1 /EN50265-2-1

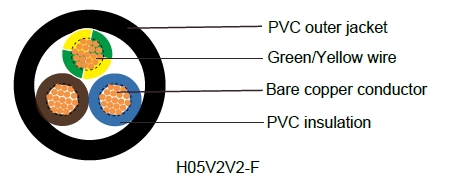

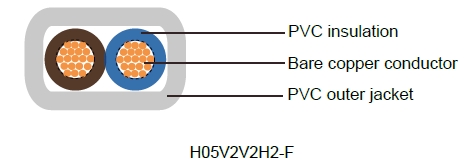

Cable Construction

Bare copper fine wire conductor

Stranded to DIN VDE 0295 cl. 5, IEC 60228 cl. 5 and HD 383

PVC core insulation T13 to VDE-0281 Part 1

Green-yellow grounding (3 conductors and above)

Color coded to VDE-0293-308

PVC outer jacket TM3

Technical Characteristics

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 15 x Ø

Static bending radius: 4 x Ø

Flexing temperature: +5º C to +90º C

Static temperature: -40º C to +90º C

Short circuit temperature: +160º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩ x km

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # x mm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/Km |

Nominal Weight kg/Km |

H05V2V2-F |

||||||

18(24/32) |

2 x 0.75 |

0.6 |

0.8 |

6.2 |

14.4 |

54.2 |

18(24/32) |

3 x 0.75 |

0.6 |

0.8 |

6.6 |

21.6 |

65 |

18(24/32) |

4 x 0.75 |

0.6 |

0.8 |

7.1 |

29 |

77.7 |

18(24/32) |

5 x 0.75 |

0.6 |

0.9 |

8 |

36 |

97.3 |

17(32/32) |

2 x 1.00 |

0.6 |

0.8 |

6.4 |

19 |

60.5 |

17(32/32) |

3 x 1.00 |

0.6 |

0.8 |

6.8 |

29 |

73.1 |

17(32/32) |

4 x 1.00 |

0.6 |

0.9 |

7.6 |

38 |

93 |

17(32/32) |

5 x 1.00 |

0.6 |

0.9 |

8.3 |

48 |

111.7 |

16(30/30) |

2 x 1.50 |

0.7 |

0.8 |

7.4 |

29 |

82.3 |

16(30/30) |

3 x 1.50 |

0.7 |

0.9 |

8.1 |

43 |

104.4 |

16(30/30) |

4 x 1.50 |

0.7 |

1.0 |

9 |

58 |

131.7 |

16(30/30) |

5 x 1.50 |

0.7 |

1.1 |

10 |

72 |

163.1 |

14(30/50) |

2 x 2.50 |

0.8 |

1.0 |

9.2 |

48 |

129.1 |

14(30/50) |

3 x 2.50 |

0.8 |

1.1 |

10 |

72 |

163 |

14(30/50) |

4 x 2.50 |

0.8 |

1.1 |

10.9 |

96 |

199.6 |

14(30/50) |

5 x 2.50 |

0.8 |

1.2 |

12.4 |

120 |

245.4 |

12(56/28) |

3 x 4.00 |

0.8 |

1.2 |

11.3 |

115 |

224 |

12(56/28) |

4 x 4.00 |

0.8 |

1.2 |

12.5 |

154 |

295 |

12(56/28) |

5 x 4.00 |

0.8 |

1.4 |

13.7 |

192 |

361 |

10(84/28) |

3 x 6.00 |

0.8 |

1.1 |

13.1 |

181 |

328 |

10(84/28) |

4 x 6.00 |

0.8 |

1.3 |

13.9 |

230 |

490 |

H05V2V2H2-F |

||||||

18(24/32) |

2 x 0.75 |

0.6 |

0.8 |

4.2 x 6.8 |

14.1 |

48 |

17(32/32) |

2 x 1.00 |

0.6 |

0.8 |

4.4 x 7.2 |

19 |

57 |