| Industrial Cables | |||

Industrial Cables

Industrial Cables

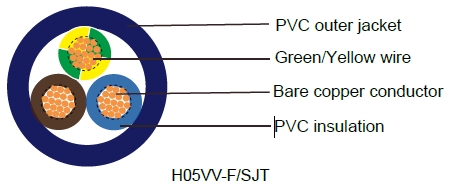

H05VV-F/SJT

Application and Description

H05VV-F/SJT cables are suited to be used for cooking and heating apparatus under the condition that cable does

not come in direct contact with hot parts of the apparatus and no other influences or heat. The cables

are suitable for fixed installation in furniture, partition walls, decoration covering and in hollow spaces of

prefabricated building parts. They are not suitable for use in open air, in industries (also permitted to tailor

workshops and of that kind) and in agriculture plants and for connecting commercial electrical tools.

Standard and Approval

<HAR> HD21.5 S3, VDE-0281 Part-5 & Part-2, UL Style 62 (SJT), VW-1, CSA 22.2 No 49, FT-1,

CE low voltage directive 73/23/EEC & 93/68/EEC., IEC 60227-5, ROHS compliant

Cable Construction

Bare copper fine wire conductor

Stranded to DIN VDE 0295 cl. 5, BS 6360 cl. 5, IEC 60228 cl. 5 and HD 383

PVC core insulation T12 to VDE-0281 Part 1

Color coded to VDE-0293-308

Green-yellow grounding (3 conductors and above)

PVC outer jacket TM2

Technical Characteristics

Working voltage VDE: 300/500 volts

Working Voltage UL/CSA: 300 volts

Test voltage: 2000 volts

Flexing bending radius: 7.5 x Ø

Static bending radius: 4 x Ø

Flexing temperature: -5º C to +70º C

Static temperature: -40º C to +70º C

Flame retardant: IEC 60332.1, VW-1

Insulation resistance: 20 MΩ x km

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # x mm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/Km |

NominaWeight kg/Km |

17(32/32) |

2 x 1 |

0.6 |

0.8 |

7.2 |

19.2 |

56 |

17(32/32) |

3 x 1 |

0.6 |

0.8 |

7.6 |

28.8 |

73 |

17(32/32) |

4 x 1 |

0.6 |

0.9 |

8.6 |

38.4 |

86 |

17(32/32) |

5 x 1 |

0.6 |

0.9 |

9.4 |

48 |

105 |

16(30/30) |

2 x 1.5 |

0.7 |

0.8 |

7.6 |

28 |

82 |

16(30/30) |

3 x 1.5 |

0.7 |

0.9 |

8.3 |

44 |

96 |

16(30/30) |

4 x 1.5 |

0.7 |

1 |

9.3 |

58 |

117 |

16(30/30) |

5 x 1.5 |

0.7 |

1.1 |

10.4 |

72 |

144 |

14(30/50) |

2 x 2.5 |

0.8 |

1 |

9.2 |

48 |

118 |

14(30/50) |

3 x 2.5 |

0.8 |

1.1 |

10 |

72 |

152 |

14(30/50) |

4 x 2.5 |

0.8 |

1.1 |

10.9 |

96 |

192 |

14(30/50) |

5 x 2.5 |

0.8 |

1.2 |

12.2 |

120 |

243 |

12(56/28) |

2 x 4 |

0.8 |

1.1 |

10.6 |

76 |

195 |

12(56/28) |

3 x 4 |

0.8 |

1.2 |

11.5 |

115 |

235 |

12(56/28) |

4 x 4 |

0.8 |

1.2 |

12.4 |

154 |

300 |

12(56/28) |

5 x 4 |

0.8 |

1.4 |

14.1 |

192 |

361 |