| Industrial Cables | |||

Industrial Cables

Industrial Cables

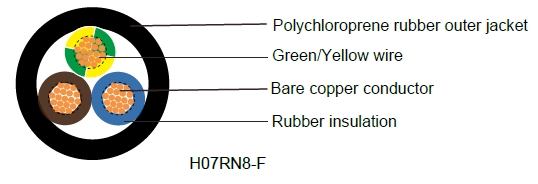

H07RN8-F

Application and Description

H07RN8-F cables particularly for use in fresh water up to 10 m depth with a maximum water temperature up to

40°C , such as the connection of submersible pumps or similar applications. Not suitable for underwater

power transmission or installation in a watercourse, or where it is possible that mechanical damage might

occur and cause a hazard. Indirect underground installation is allowed provided that there is mechanically

protection of the cables. H07RN8-F cables are manufactured according to the Standard and Approval CEI 20-

19/16 (CENELEC HD 22.16). It is the only cable that the installation Standard and Approval CEI 64-8 at

section 702 allows for installation in swimming pools and fountains. For connections liable to moderate

mechanical stresses, i.e. industrial or agricultural workshop apparatus, large boilers, heater plates, electric

tools such as drills and disk saws, electric appliances, portable motors and generators on building sites;

also for fixed installations along floors or shelving on temporary job sites, for connecting structural elements

in lifting apparatus, machinery, etc. Suitable for applications up to 1000 V for adequately protected fixed

installations ( i.e. inside pipes or equipment) as well as for rotor connections to lifting apparatus motors. They

are Ozone, UV & weather resistant

Standard and Approval

<HAR> HD22.16 S1, VDE-0282 Part-16, CEI 20-19 p.16,

CE low voltage directive 73/23/EEC & 93/68/EEC., ROHS compliant

Cable Construction

Fine bare copper strands

Strands to VDE-0295 Class-5, IEC 60228 Class-5

Rubber core insulation EI4 to VDE-0282 Part-1

Color code VDE-0293-308 and HD 186

Polychloroprene rubber (neoprene) jacket EM2

Technical Characteristics

Working voltage: 450/750 volts

Test voltage: 2500 volts

Flexing bending radius: 6.0 x Ø

Fixed bending radius: 4.0 x Ø

Flexing Temperature: -25º C to +60º C

Fixed Temperature: -40º C to +60º C

Max Water Temperature: +40º C

Short circuit temperature: +250 º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩ x km

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # x mm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm min-max |

Nominal Copper Weight kg/Km |

Nominal Weight kg/Km |

2 x 1 |

0.8 |

1.3 |

7.7-10 |

19 |

89 |

|

17(32/32) |

3 x 1 |

0.8 |

1.4 |

8.3-10.7 |

29 |

111 |

17(32/32) |

4 x 1 |

0.8 |

1.5 |

9.2-11.9 |

38 |

146 |

1 x 1.5 |

0.8 |

1.4 |

5.7-7.1 |

14.4 |

59 |

|

16(30/30) |

2 x 1.5 |

0.8 |

1.5 |

8.5-11.0 |

29 |

135 |

16(30/30) |

3 x 1.5 |

0.8 |

1.6 |

9.2-11.9 |

43 |

165 |

16(30/30) |

4 x 1.5 |

0.8 |

1.7 |

10.2-13.1 |

58 |

200 |

16(30/30) |

5 x 1.5 |

0.8 |

1.8 |

11.2-14.4 |

72 |

240 |

16(30/30) |

7 x 1.5 |

0.8 |

2.6 |

14.5-17.5 |

101 |

385 |

16(30/30) |

12 x 1.5 |

0.8 |

2.9 |

17.6-22.4 |

173 |

516 |

16(30/30) |

19 x 1.5 |

0.8 |

3.2 |

20.7-26.3 |

274 |

800 |

16(30/30) |

24 x 1.5 |

0.8 |

3.5 |

24.3-30.7 |

346 |

882 |

1 x 2.5 |

0.9 |

1.4 |

6.3-7.9 |

24 |

72 |

|

14(50/30) |

2 x 2.5 |

0.9 |

1.7 |

10.2-13.1 |

48 |

195 |

14(50/30) |

3 x 2.5 |

0.9 |

1.8 |

10.9-14.0 |

72 |

235 |

14(50/30) |

4 x 2.5 |

0.9 |

1.9 |

12.1-15.5 |

96 |

290 |

14(50/30) |

5 x 2.5 |

0.9 |

2 |

13.3-17.0 |

120 |

345 |

14(50/30) |

7 x 2.5 |

0.9 |

2.8 |

16.5-20.0 |

168 |

520 |

14(50/30) |

12 x 2.5 |

0.9 |

3.1 |

20.6-26.2 |

288 |

810 |

14(50/30) |

19 x 2.5 |

0.9 |

3.5 |

25.5-31.0 |

456 |

1200 |

14(50/30) |

24 x 2.5 |

0.9 |

3.9 |

28.8-36.4 |

576 |

1650 |

1 x 4 |

1 |

1.5 |

7.2-9.0 |

38 |

99 |

|

12(56/28) |

2 x 4 |

1 |

1.8 |

11.8-15.1 |

77 |

270 |

12(56/28) |

3 x 4 |

1 |

1.9 |

12.7-16.2 |

115 |

320 |

12(56/28) |

4 x 4 |

1 |

2 |

14.0-17.9 |

154 |

395 |

12(56/28) |

5 x 4 |

1 |

2.2 |

15.6-19.9 |

192 |

485 |

12(56/28) |

7 x 4 |

1 |

3.1 |

18.2-21.8 |

269 |

681 |

1 x 6 |

1 |

1.6 |

7.9-9.8 |

58 |

130 |

|

10(84/28) |

3 x 6 |

1 |

2.1 |

14.1-18.0 |

173 |

495 |

10(84/28) |

4 x 6 |

1 |

2.3 |

15.7-20.0 |

230 |

610 |

10(84/28) |

5 x 6 |

1.2 |

3.6 |

17.5-22.2 |

288 |

760 |

1 x 10 |

1.2 |

1.8 |

9.5-11.9 |

96 |

230 |

|

8(80/26) |

3 x 10 |

1.2 |

3.3 |

19.1-24.2 |

288 |

880 |

8(80/26) |

4 x 10 |

1.2 |

3.4 |

20.9-26.5 |

384 |

1060 |

8(80/26) |

5 x 10 |

1.2 |

3.6 |

22.9-29.1 |

480 |

1300 |

1 x 16 |

1.2 |

1.9 |

10.8-13.4 |

154 |

320 |

6(128/26) |

3 x 16 |

1.2 |

3.5 |

21.8-27.6 |

461 |

1090 |

6(128/26) |

4 x 16 |

1.2 |

3.6 |

23.8-30.1 |

614 |

1345 |

6(128/26) |

5 x 16 |

1.2 |

3.9 |

26.4-33.3 |

768 |

1680 |

4 (200/26) |

1 x25 |

1.4 |

2 |

12.7-15.8 |

240 |

450 |

4 (200/26) |

4 x 25 |

1.4 |

4.1 |

28.9-36.6 |

960 |

1995 |

4 (200/26) |

5 x 25 |

1.4 |

4.4 |

32.0-40.4 |

1200 |

2470 |

1 x 35 |

1.4 |

2.2 |

14.3-17.9 |

336 |

605 |

|

2 (280/26) |

3 x 35 |

1.4 |

4.1 |

29.3-37.1 |

1008 |

1900 |

2 (280/26) |

4 x 35 |

1.4 |

4.4 |

32.5-41.1 |

1344 |

2645 |

2 (280/26) |

5 x 35 |

1.4 |

4.7 |

37.0-45.0 |

1680 |

2810 |

1 x 50 |

1.6 |

2.4 |

16.5-20.6 |

480 |

825 |

|

1 (400/26) |

4 x 50 |

1.6 |

4.8 |

37.7-47.5 |

1920 |

3635 |

1 (400/26) |

5 x 50 |

1.6 |

5.1 |

40.0-50.8 |

2400 |

4050 |

1 x 70 |

1.6 |

2.6 |

18.6-23.3 |

672 |

1090 |

|

2/0 (356/24) |

4 x 70 |

1.6 |

5.2 |

42.7-54.0 |

2688 |

4830 |

3/0 (485/24) |

1 x 95 |

1.8 |

2.8 |

20.8-26.0 |

912 |

1405 |

3/0 (485/24) |

4 x 95 |

1.8 |

5.9 |

48.4-61.0 |

3648 |

6320 |

1x 120 |

1.8 |

3 |

22.8-28.6 |

1152 |

1746 |

|

4/0 (614/24) |

4 x 120 |

1.8 |

6 |

53.0-66.0 |

4608 |

6830 |

1 x 150 |

2 |

3.2 |

25.2-31.4 |

1440 |

1887 |

|

300 MCM (765/24) |

4 x 150 |

2 |

6.4 |

58.0-73.0 |

5760 |

8320 |

350 MCM (944/24) |

1 x 185 |

2.2 |

3.4 |

27.6-34.4 |

1776 |

2274 |

350 MCM (944/24) |

4 x 185 |

2.2 |

6.8 |

64.0-80.0 |

7104 |

9800 |

500 MCM (1221/24) |

1x 240 |

2.4 |

3.5 |

30.6-38.3 |

23.4 |

2956 |

500 MCM (1221/24)

|

4x 240 |

2.4 |

7.2 |

72.0-90.0 |

9216 |

12100 |

1 x 300 |

2.6 |

3.6 |

33.5-41.9 |

2880 |

3479 |