| Industrial Cables | |||

JIS Industrial Cables

CCV

Application and Description:

CCV cables are used for supervisory electrical equipment, station control circuits, outdoor, suitable installation in dry or wet cable trenches.

Reference Standard:

IEC 60502-1

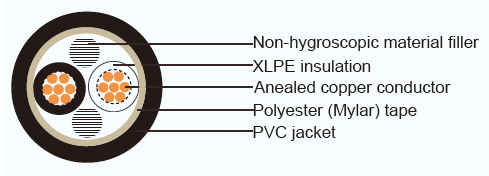

Cable Construction:

Conductor: Stranded annealed copper wires, Sizes: 1.5 mm2 up to 10 mm2 Insulation: Cross-linked polyethylene(XLPE)

Color : 2-4 cores-Black, White, Red and Green ,More than 4 cores: Black core with marking numbers Filler: Non-hygroscopic material(optional)

Binding tape: Polyester (Mylar) tape (optional)

Sheath: Polyvinyl chloride (PVC), Black color (A special flame retardant sheath can be supplied)

Technical Characteristics:

Maximum conductor temperature 90oC

Circuit voltage not exceeding 600 volts

Test voltage 3500 volts

Cable Parameter:

| NO. OF CORES | CONDUCTOR | THICKNESS OF INSULATION | THICKNESS OF SHEATH |

OVERALL DIAMETER | MAXIMUM CONDUCTOR RESISTANCE (AT 20°C) | CABLE WEIGHT | ||

| NOMINAL CROSS- SECTIONAL AREA |

NO.& DIA. OF WIRES |

DIAMETER | ||||||

| MM2 | MM | MM | MM | MM | MM | OHM/KM | KG/KM | |

| 2 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 10.5 | 12.1 | 130 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 11.5 | 7.41 | 160 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 12.5 | 4.61 | 200 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 13.5 | 3.08 | 260 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 15.5 | 1.83 | 350 | |

| 3 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 11.0 | 12.1 | 160 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 12.0 | 7.41 | 200 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 13.0 | 4.61 | 260 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 14.5 | 3.08 | 330 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 16.5 | 1.83 | 470 | |

| 4 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 12.0 | 12.1 | 190 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 13.0 | 7.41 | 250 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 14.5 | 4.61 | 320 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 15.5 | 3.08 | 420 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 18.0 | 1.83 | 600 | |

| 5 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 13.0 | 12.1 | 230 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 14.0 | 7.41 | 290 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 15.5 | 4.61 | 380 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 17.0 | 3.08 | 500 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 19.5 | 1.83 | 730 | |

| 6 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 13.5 | 12.1 | 260 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 15.0 | 7.41 | 340 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 16.5 | 4.61 | 450 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 18.5 | 3.08 | 590 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 21.0 | 1.83 | 850 | |

| 7 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 13.5 | 12.1 | 270 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 15.0 | 7.41 | 360 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 16.5 | 4.61 | 480 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 18.5 | 3.08 | 640 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 21.0 | 1.83 | 940 | |

| 8 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 15.0 | 12.1 | 320 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 16.5 | 7.41 | 410 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 18.5 | 4.61 | 550 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 20.5 | 3.08 | 740 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 23.5 | 1.83 | 1,090 | |

| 10 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 17.0 | 12.1 | 380 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 18.5 | 7.41 | 500 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 20.5 | 4.61 | 670 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 23.0 | 3.08 | 900 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 26.5 | 1.83 | 1,330 | |

| 12 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 17.5 | 12.1 | 430 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 19.0 | 7.41 | 570 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 21.5 | 4.61 | 780 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 23.5 | 3.08 | 1,050 | |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 27.5 | 1.83 | 1,560 | |

| 15 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 19.0 | 12.1 | 510 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 21.0 | 7.41 | 690 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 23.5 | 4.61 | 950 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 26.0 | 3.08 | 1,280 | |

| 20 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 21.0 | 12.1 | 650 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 23.0 | 7.41 | 880 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 26.0 | 4.61 | 1,220 | |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 29.0 | 3.08 | 1,660 | |

| 30 | 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 24.0 | 12.1 | 920 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8(1.9) | 27.0 | 7.41 | 1,250 | |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8(1.9) | 30.5 | 4.61 | 1,750 | |