| Industrial Cables | |||

Industrial Cables-British Standard

318B to BS 6500(New BS EN 50525-3-11)

Application and Description

318B to BS 6500(New BS EN 50525-3-11) cables may be used as an indoor general wiring cable primarily for installations in public areas. Examples include use on pendant lighting drops or as a general supply lead within hospital or airport projects. 318B to BS 6500(New BS EN 50525-3-11) cables are suitable for installations where fire, smoke emission and toxic fumes create a potential threat to life and equipment. 318B is equivalent to harmonized code H05Z1Z1-F.

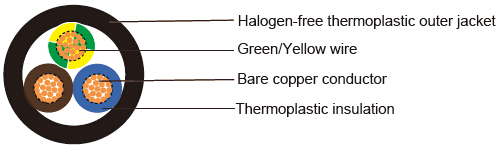

Cable Construction

-

Fine bare copper strands

Stranding to BS 6360 CL-5 or IEC 60228 CL-5Halogen-fee thermoplastic TI6 core insulation

Green/Yellow grounding (3 conductors and above)

Halogen-fee thermoplastic TM7 outer jacket

Core Identification

-

2Cores: Brown, Blue

3Cores: Brown, Blue and Green/Yellow

4Cores: Brown, Grey, Black and Green/Yellow

5Cores: Brown, Blue, Grey, Black and Green/Yellow

Technical Characteristics

-

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 6xOverall diameter

Fixed bending radius: 4xOverall diameter

Operating temperature: -30º C to +90º C

Short circuit temperature: +160º C

- Insulation resistance: 20 MΩxkm

Halogen free acc. to EN 50267-2-1 / IEC 60754-1

Smoke density acc. to EN 50268-2 / IEC 61034-2

Corrosivity of gases acc. to EN 50267-2-2, IEC 60754-2

Flame retardancy acc. to EN 50265-2-1, IEC 60332-1

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| 3182B | ||||||

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 6.2 | 14.4 | 58 |

| 17(32/32) | 2x1 | 0.6 | 0.8 | 6.6 | 19 | 67 |

| 16(30/30) | 2x1.5 | 0.7 | 0.8 | 7.4 | 29 | 87 |

| 14(50/30) | 2x2.5 | 0.8 | 1.0 | 9.3 | 48 | 138 |

| 12(56/28) | 2x4 | 0.8 | 1.1 | 10.6 | 76.8 | 190 |

| 3183B | ||||||

| 18(24/32) | 3x0.75 | 0.6 | 0.8 | 6.6 | 21.6 | 68 |

| 17(32/32) | 3x1 | 0.6 | 0.8 | 6.9 | 29 | 81 |

| 16(30/30) | 3x1.5 | 0.7 | 0.9 | 8.1 | 43 | 109 |

| 14(50/30) | 3x2.5 | 0.8 | 1.1 | 10.1 | 72 | 172 |

| 12(56/28) | 3x4 | 0.8 | 1.2 | 11.5 | 115.2 | 242 |

| 3184B | ||||||

| 18(24/32) | 4x0.75 | 0.6 | 0.8 | 7.1 | 29 | 81 |

| 17(32/32) | 4x1 | 0.6 | 0.9 | 7.7 | 38 | 101 |

| 16(30/30) | 4x1.5 | 0.7 | 1.0 | 9 | 58 | 117 |

| 14(50/30) | 4x2.5 | 0.8 | 1.1 | 11 | 96 | 210 |

| 12(56/28) | 4x4 | 0.8 | 1.4 | 12.5 | 153.6 | 298 |

| 3185B | ||||||

| 18(24/32) | 5x0.75 | 0.6 | 0.9 | 8 | 36 | 102 |

| 17(32/32) | 5x1 | 0.6 | 0.9 | 8.4 | 48 | 107 |

| 16(30/30) | 5x1.5 | 0.7 | 1.1 | 10 | 72 | 169 |

| 14(50/30) | 5x2.5 | 0.8 | 1.2 | 12.3 | 120 | 260 |

| 12(56/28) | 5x4 | 0.8 | 1.4 | 14.1 | 192 | 371 |