| Industrial Cables | |||

Industrial Cables-British Standard

318TRS to BS 6500

Application and Description

318TRS to BS 6500 cables are suitable for use with electronics and electrical equipment such as appliances, small hand tools and office equipment, where the cables may be subject to light and medium stresses in both dry and damp environments. They can be used in flat irons, soldering irons, kitchen aids, toasters, stoves in connections with light commercial electric tools. They are also suitable for fixed installation in furniture, decorative coverings, wall partitions and pre-fabricated building parts. 318TRS is equivalent to harmonized code H05RR-F.

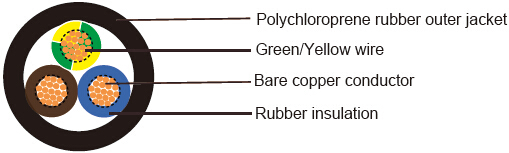

Cable Construction

-

Fine bare copper strands

Stranding to BS 6360 CL-5 or IEC 60228 CL-5

Rubber core insulation EI4

Green/Yellow grounding, 3 conductors and above

Polychloroprene rubber (neoprene) jacket EM3

Core Identification

-

2Cores: Brown, Blue

3Cores: Brown, Blue and Green/Yellow

4Cores: Brown, Grey, Black and Green/Yellow

5Cores: Brown, Blue, Grey, Black and Green/Yellow

Technical Characteristics

-

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 8xOverall diameter

Fixed bending radius: 6xOverall diameter

Temperature range: -30º C to +60º C

Short circuit temperature: +200 º C

Flame retardant: IEC 60332.1

- Insulation resistance: 20 MΩxkm

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter min-max mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| 3182TRS | ||||||

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 5.7-7.4 | 14.4 | 61 |

| 17(32/32) | 2x1 | 0.6 | 0.9 | 6.1-8.0 | 19.0 | 73 |

| 16(30/30) | 2x1.5 | 0.8 | 1.0 | 7.6-9.8 | 29.0 | 115 |

| 14(50/30) | 2x2.5 | 0.9 | 1.1 | 9.0-11.6 | 48.0 | 160 |

| 3183TRS | ||||||

| 18(24/32) | 3x0.75 | 0.6 | 0.9 | 6.2-8.1 | 21.6 | 75 |

| 17(32/32) | 3x1 | 0.6 | 0.9 | 6.5-8.5 | 29.0 | 86 |

| 16(30/30) | 3x1.5 | 0.8 | 1.0 | 8.0-10.4 | 43.0 | 135 |

| 14(50/30) | 3x2.5 | 0.9 | 1.1 | 9.6-12.4 | 72.0 | 191 |

| 3184TRS | ||||||

| 18(24/32) | 4x0.75 | 0.6 | 0.9 | 6.8-8.8 | 28.8 | 94 |

| 17(32/32) | 4x1 | 0.6 | 0.9 | 7.1-9.3 | 38.4 | 105 |

| 16(30/30) | 4x1.5 | 0.8 | 1.1 | 9.0-11.6 | 58.0 | 165 |

| 14(50/30) | 4x2.5 | 0.9 | 1.2 | 10.7-13.8 | 96 | 235 |

| 3185TRS | ||||||

| 18(24/32) | 5x0.75 | 0.6 | 1.0 | 7.6-9.9 | 36 | 110 |

| 17(32/32) | 5x1 | 0.6 | 1.0 | 8.0-10.3 | 48.0 | 130 |

| 16(30/30) | 5x1.5 | 0.8 | 1.1 | 9.8-12.7 | 72.0 | 190 |

| 14(50/30) | 5x2.5 | 0.9 | 1.3 | 11.9-15.3 | 120 | 285 |